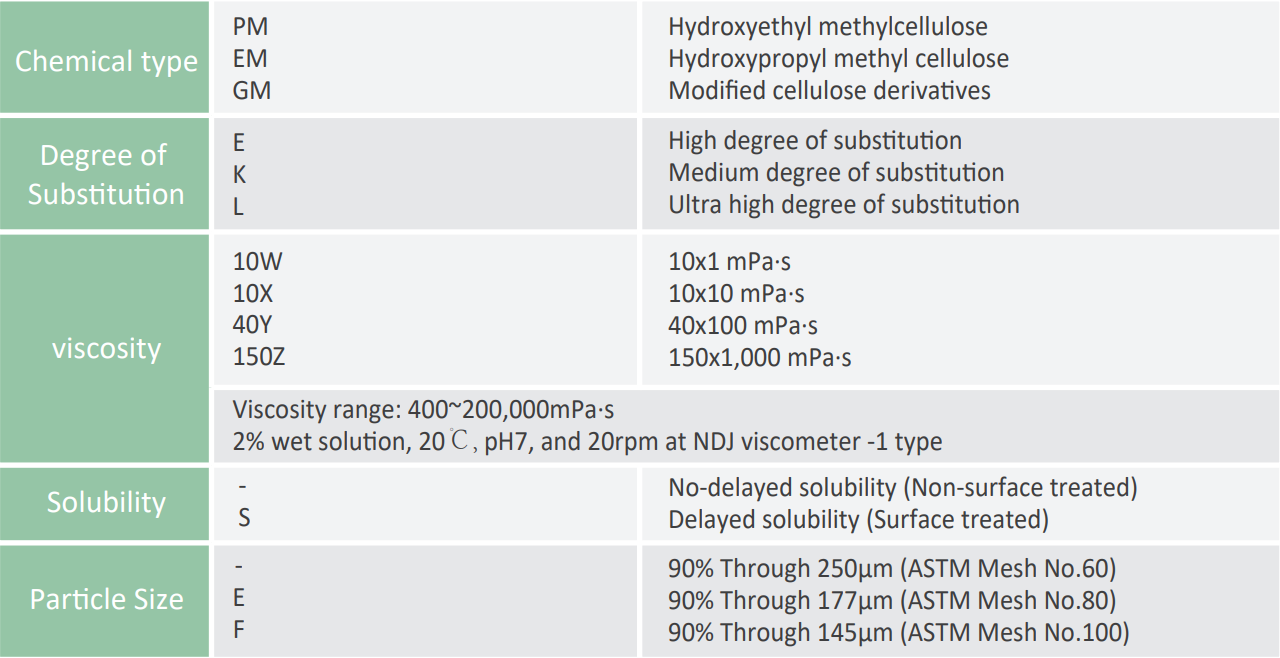

NOMENCLATURE & CLASSIFICATION

MATECEL® is classified into pure and modified grades. Pure grades are also divided into HPMC(Hydroxypropyl Methyl Cellulose) and HEMC(Hydroxyethyl Methyl Cellulose).

PMK-150ZS(HPMC, Degree of subsituion K, Viscosity 150000mPa·s, Delayed Solubility)

GMK Grade

GMK grades are finely modified to improve the rheological properties of cellulose ethers in accordance with various application requirements such as additional thickening, betier workability, less stickiness, longer open time, etc.

Modified grades are especially produced through chemical reactions, physical blending of organic or inorganic additives. The viscosity range varies from under 400mPa·s to over 200,000mPa·s.

Classification

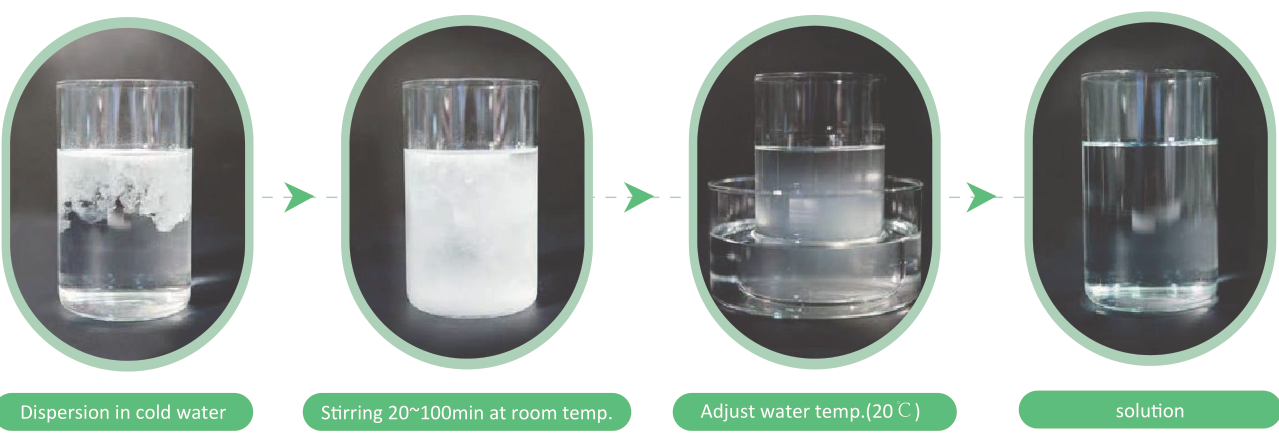

HOW TO PREPARE MATECEL® SOLUTIONS

The surface-treated powder is specially developed to prevent lumping in wet blending applications such as paints and emulsion-based applications. This kind of powder can be directly placed into cold water. With time, a fully-developed solution with the right viscosity is formed through continuous stirring of the solution.

SOLUBILITY

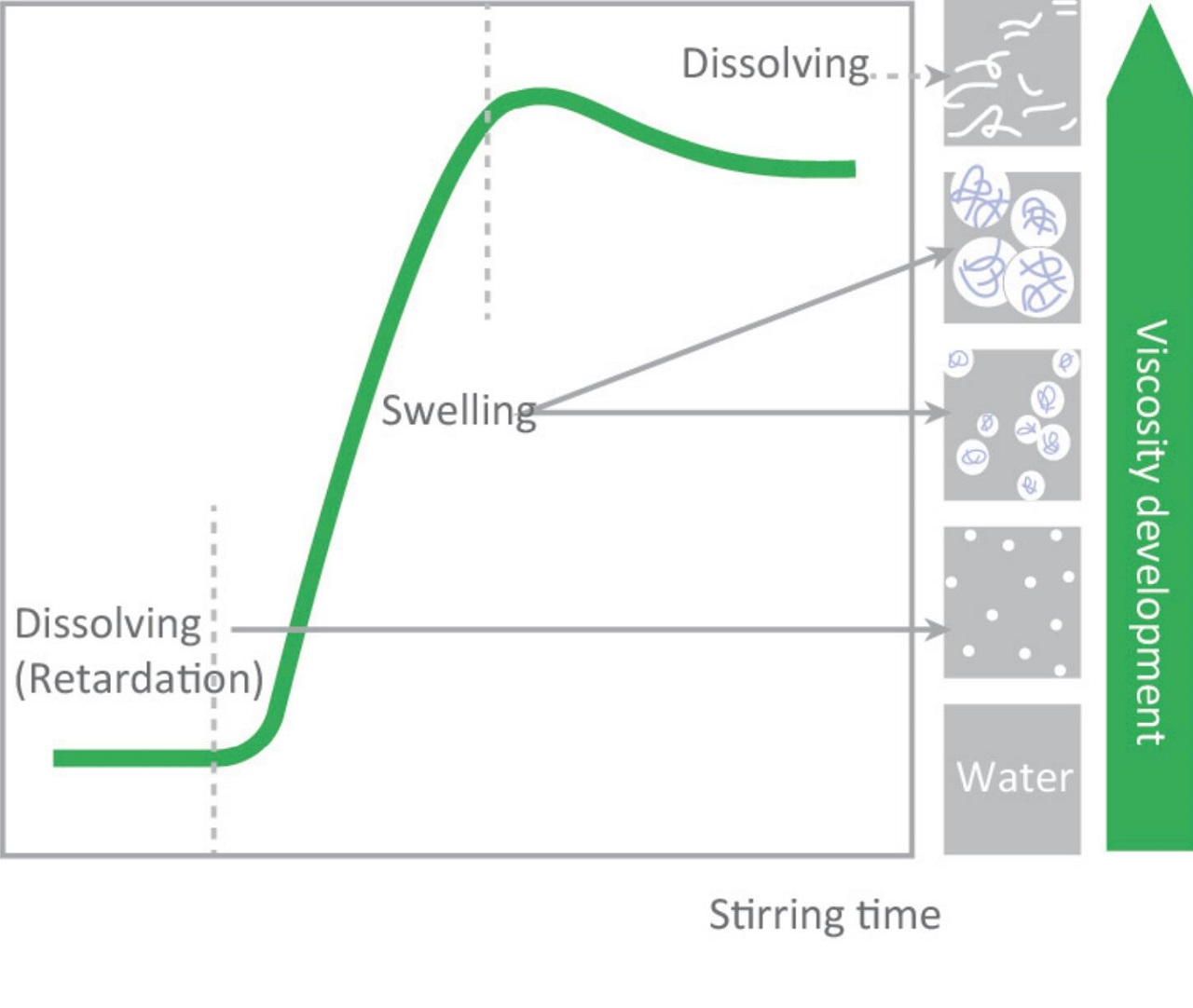

Dissolution of MATECEL®

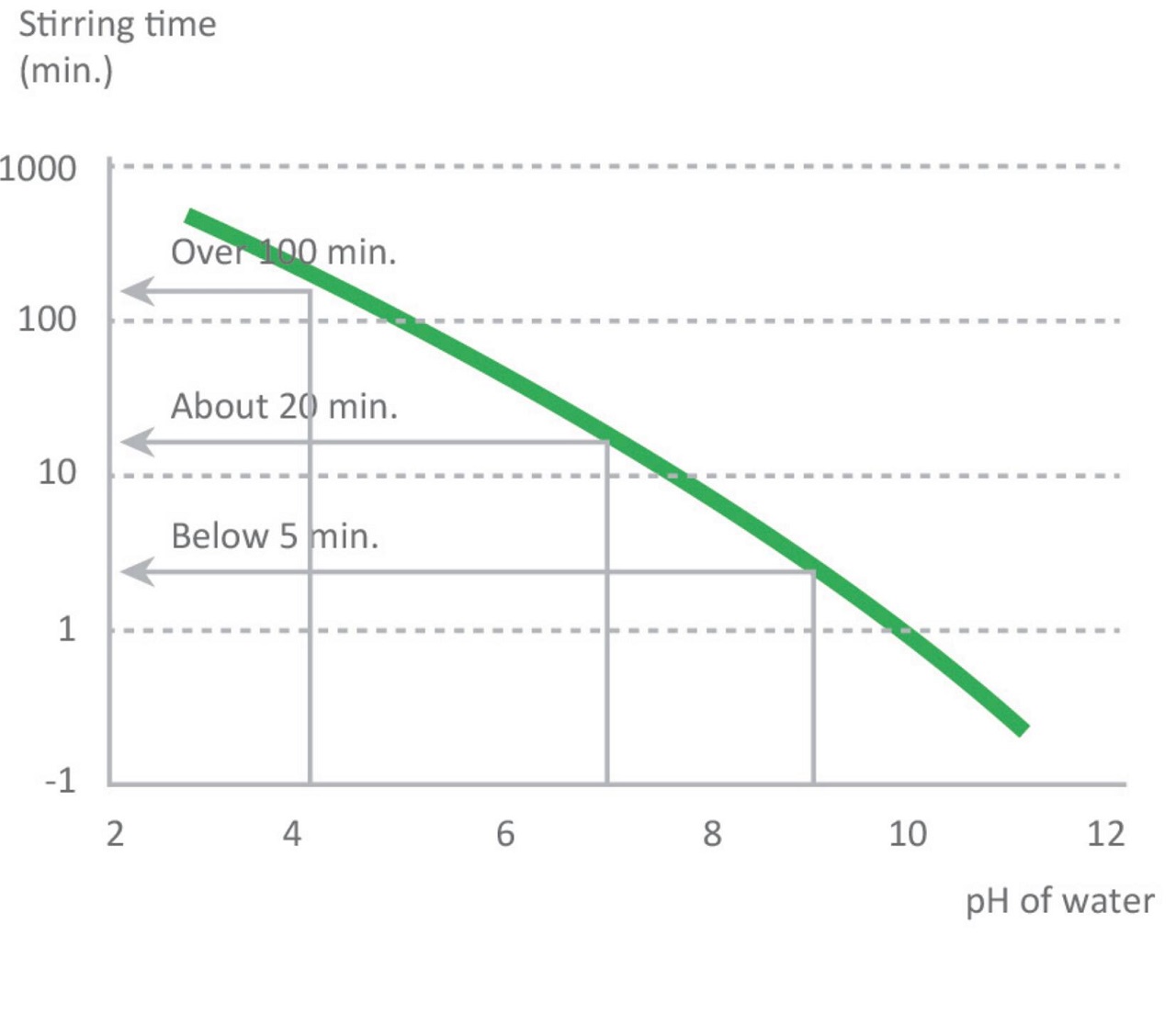

When it comes to water solubility levels and speed, the general dissolution mechanism of MATECEL® is shown in the graph below.

Non-surface treated MATECEL®

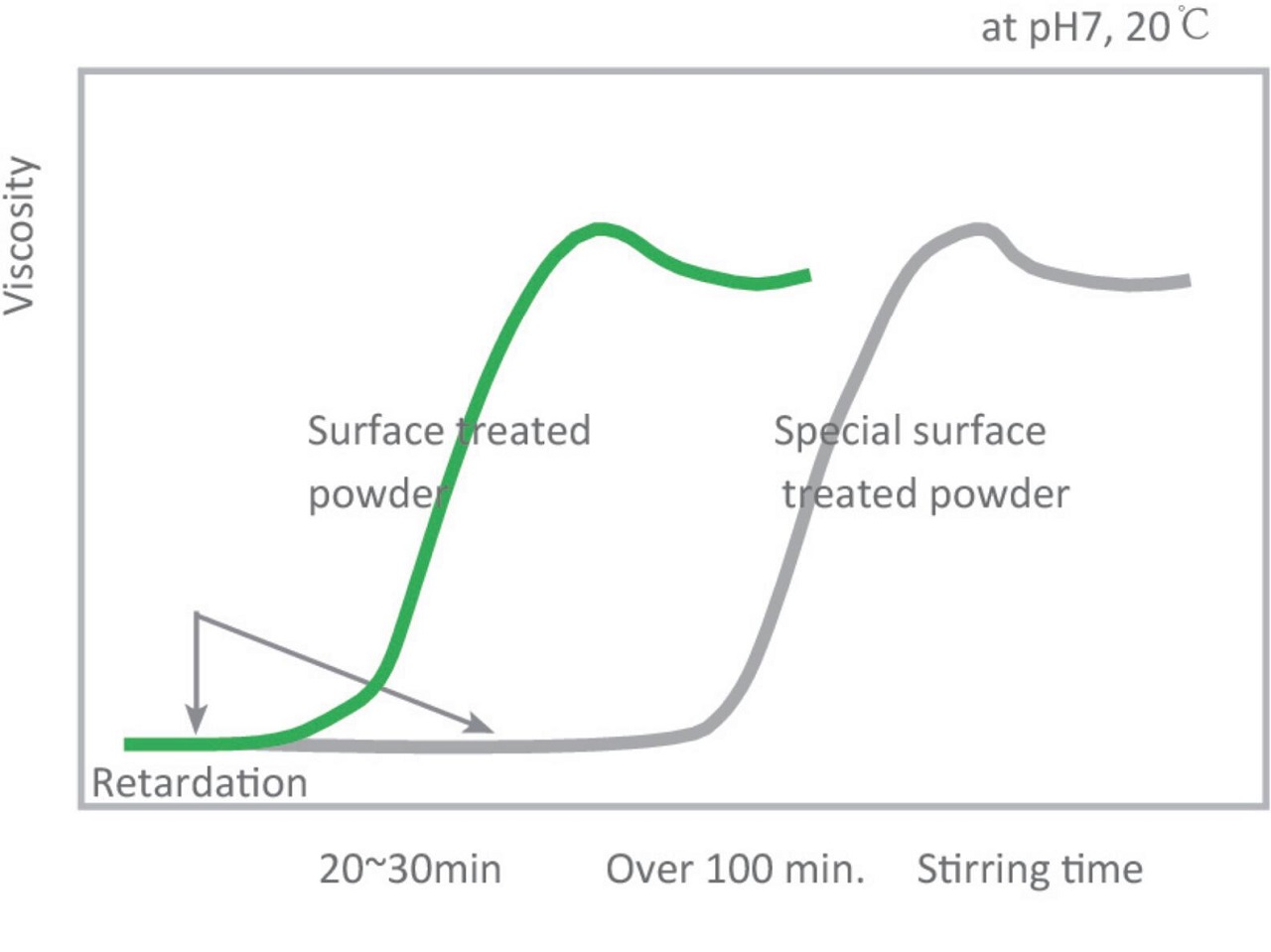

The viscosity measuring of non-surface treated MATECEL® is impossible in cold water due to lump formations. The retardation time of surface-treated MATECEL® Approximates to about 20 minutes at HP 7. However, the higher the PH of the solution is, the shorter the retardation time will be.

The effect of pH on MATECEL® dissolving times

The viscosity development time is dependent upon the pH of the solution fie surface-treated grades. The higher the pH of the solutions is, the shorter the retardation time will be. For paint applications, long-regarded grades are more suitable because of the high pH conditions (CaCO₃,ammonia,etc.) of the applications.

VISCOSITY

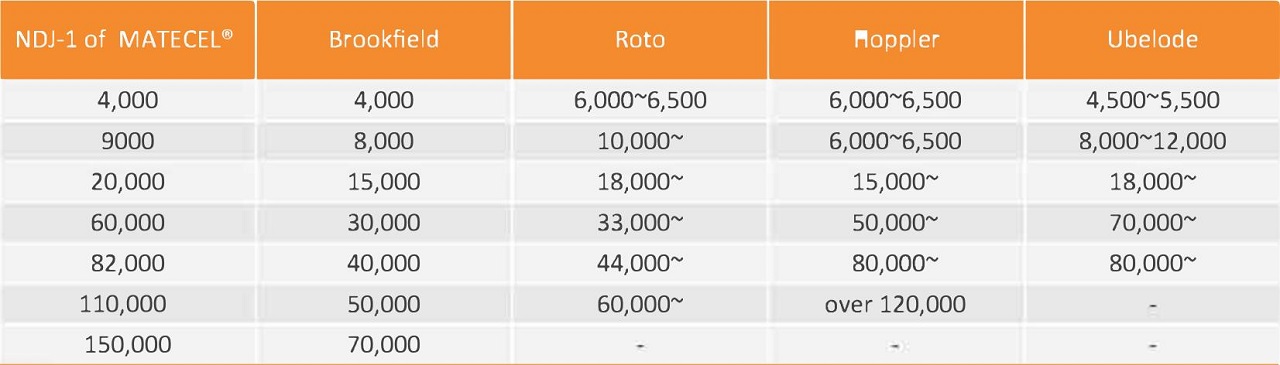

Viscosity comparison through various measurements. Viscosity is a resistance force (based on the flow rate, gravity force, rotation resistance of the product, etc.).

In general Hoppler (=Falling B) and Ubelode all types measure Newtonian solutions

Note that measured values could vary with the types of NDJ viscometer

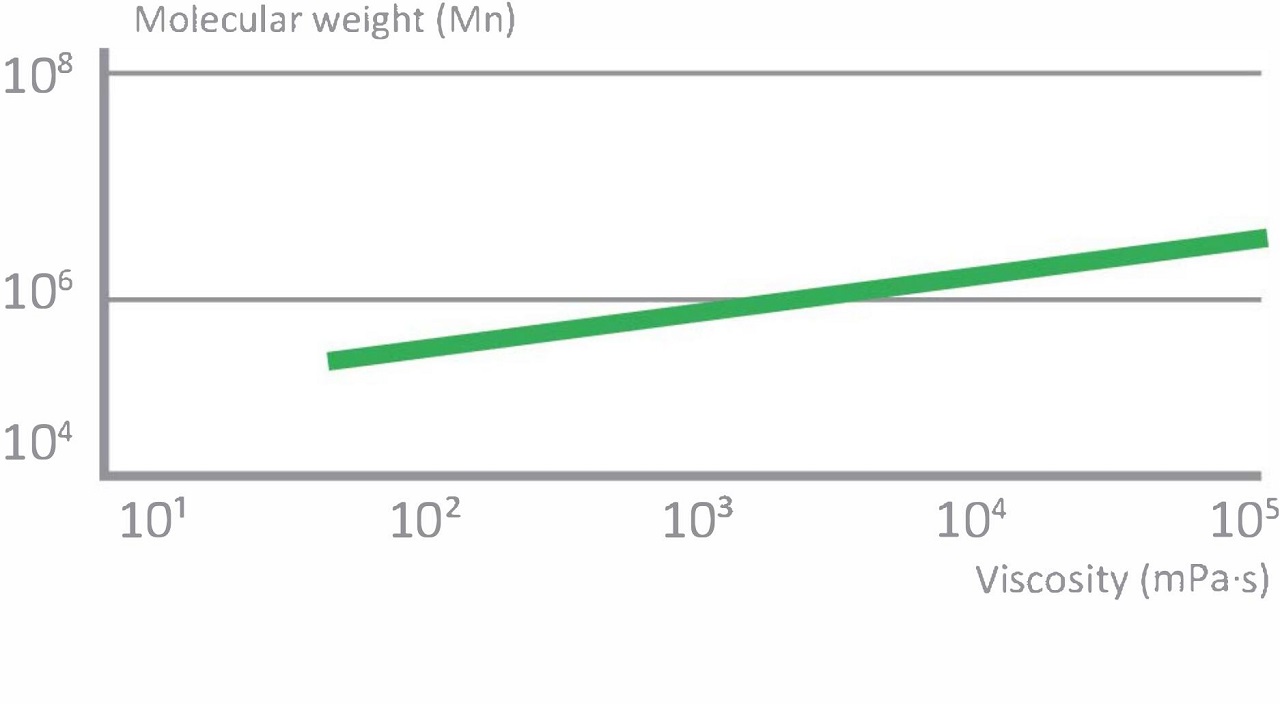

Relationship between viscosity and molecular weight

The viscosity of a solution is proportional to the weight or chain length of the MATECEL molecularAverage molecular weight of MATECEL varies from 400 to 200000.

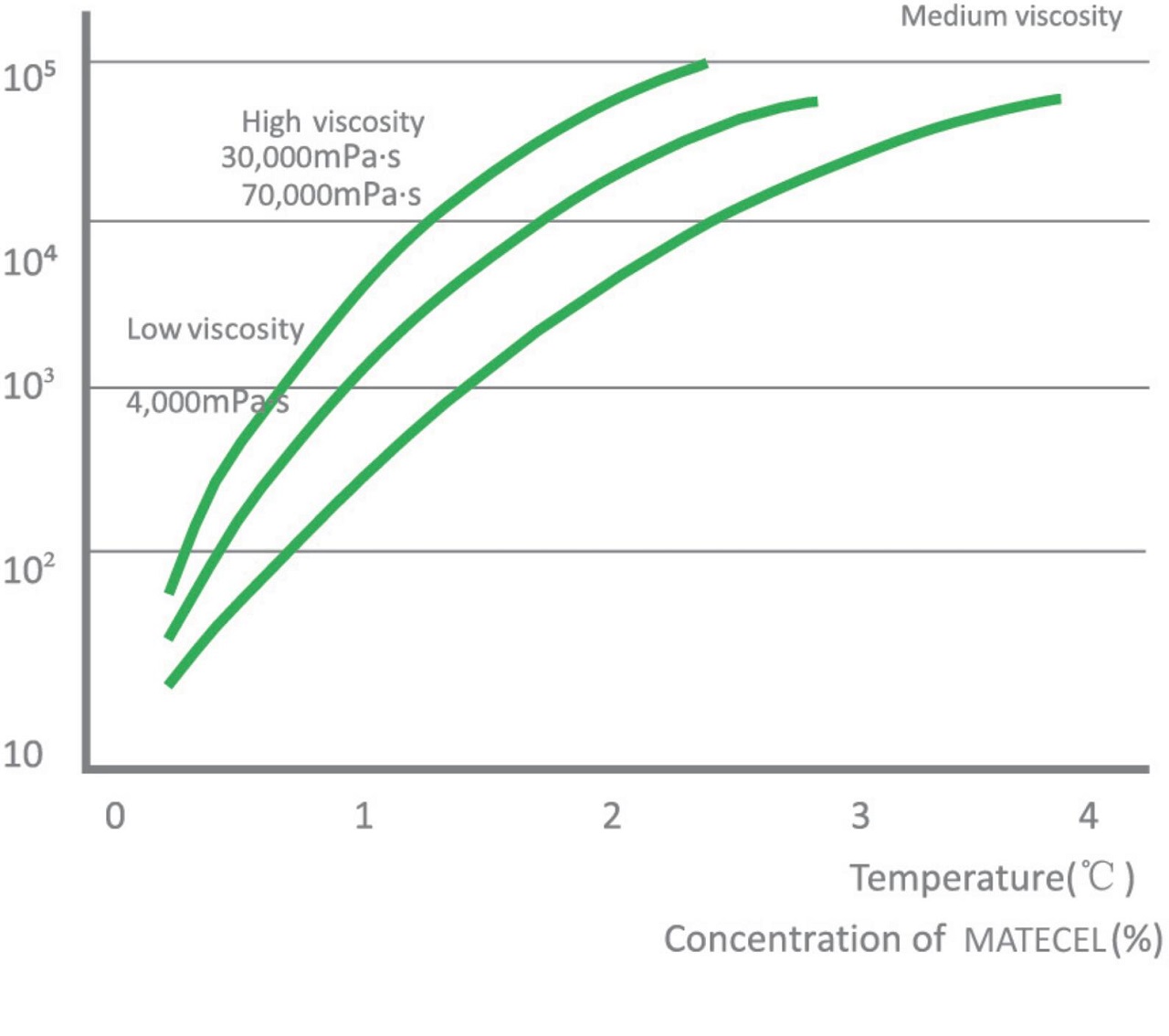

Relationship between viscosity and concentration

In general, viscosity is proportional to the concentration of the solution. Limited to about 2.5% for high viscosity grade.(over 50,000 mPas, 2% solution)

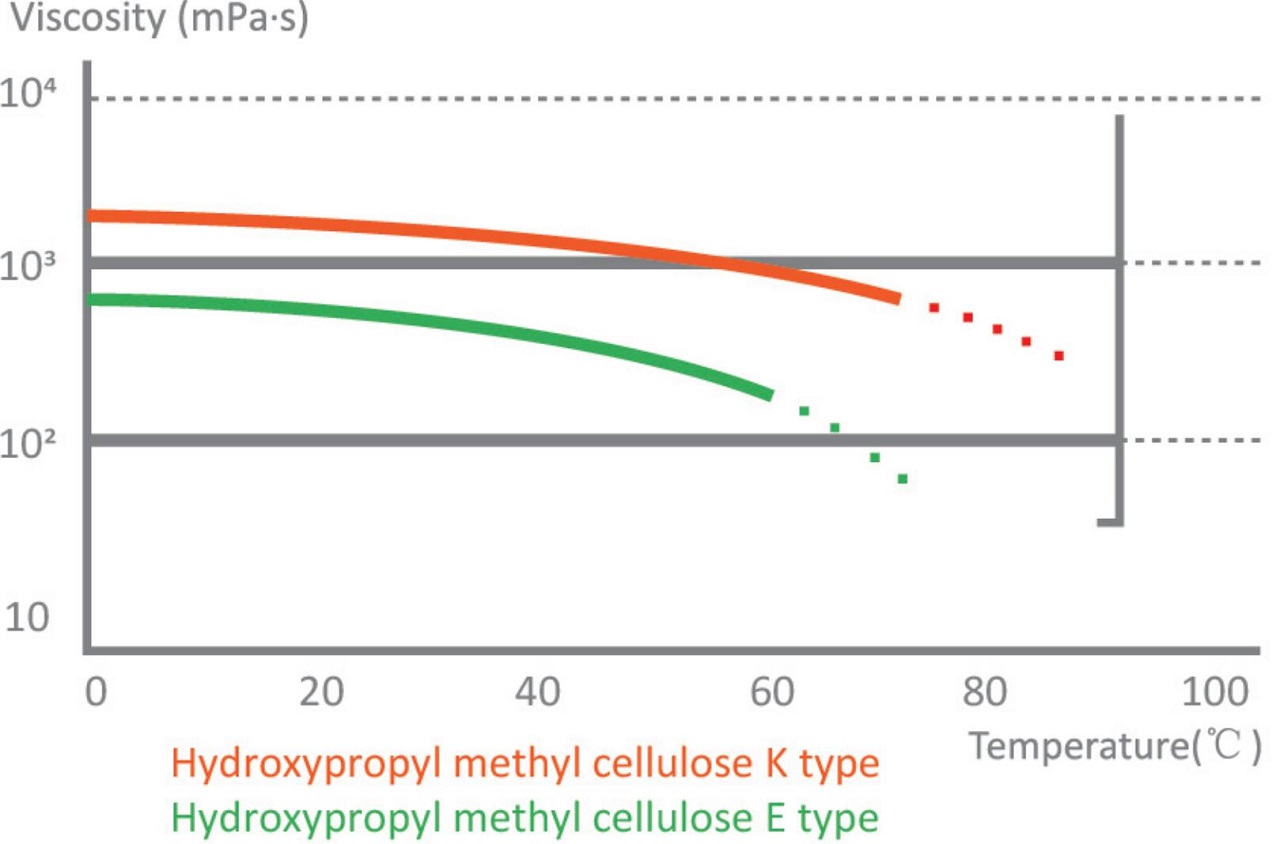

Relationship between viscosity and temperature

The viscosity of MATECEL solution depends on its temperature. As the temperature increases its viscosity gradually decreases when it reaches a certain temperature, the viscosity decreases sharply. The trend is shown in the dotted line. That certain temperature is called Gel-point.

MAIN BENEFITS

Thickening effect

MATECEL® is used very often as a thickener in building applications as it prevents segregation and improves the cohesion of the formulation components.

The viscosity of MATECEL® depends on the degree of polymerization, contraction, temperature, shear rate, concentration of dissolved salts, and modification.

In dry mixing production and mortar, the thickening power of pure grades is related to their solution viscosity. On the other hand, the mortar viscosity of modified grades is not necessarily proportional to the solution viscosity.

![Main] Benefits总.1.1jpg.jpg Main] Benefits总.1.1jpg.jpg](https://tr.hpmc.com/data/upload/ueditor/20230812/64d6fcb00bf21.jpg)

Shijiazhuang Henggu Jianxin Cellulose Co., Ltd.

Yüksek Teknoloji Dairesel Kimyasal Endüstri Parkı, Xincheng Kasabası, Xinji Şehri, Hebei Eyaleti Posta Kodu: 052360

Copyright 2023 Shijiazhuang Henggu Jianxin Cellulose Co., Ltd. Her hakkı saklıdır